Dominique Barnes could turn you off of shrimp in a heartbeat. She could tell you horror stories of turtles and sharks caught as bycatch in nets, or about the antibiotics pumped into framed shrimp that seep into the ocean. Don’t even get her started on the terrible working conditions that shrimp workers often endure, peeling and processing shrimp for over 12 hours a day. Yet rather than trying to stop Americans from consuming the over one billion pounds of shrimp they eat each year, Dominique has taken the high road: she’s creating a better shrimp.

Dominique is the co-founder of biotech startup New Wave Foods , which produces lab-made shrimp. She and her co-founder Michelle Wolf have created a plant protein and algae-based “shrimp,” or SHR!MP™—the latest in a string of biotech food advances. You may have read about lab-grown meatballs, burgers, and steaks—but few companies have come as far as Dominique and Michelle, who have already started demonstrating their product at Google’s cafeteria. (They’re also in the process of trademarking that exclamation point in shrimp.)

Illustration by Catherine Lamb

Illustration by Catherine Lamb

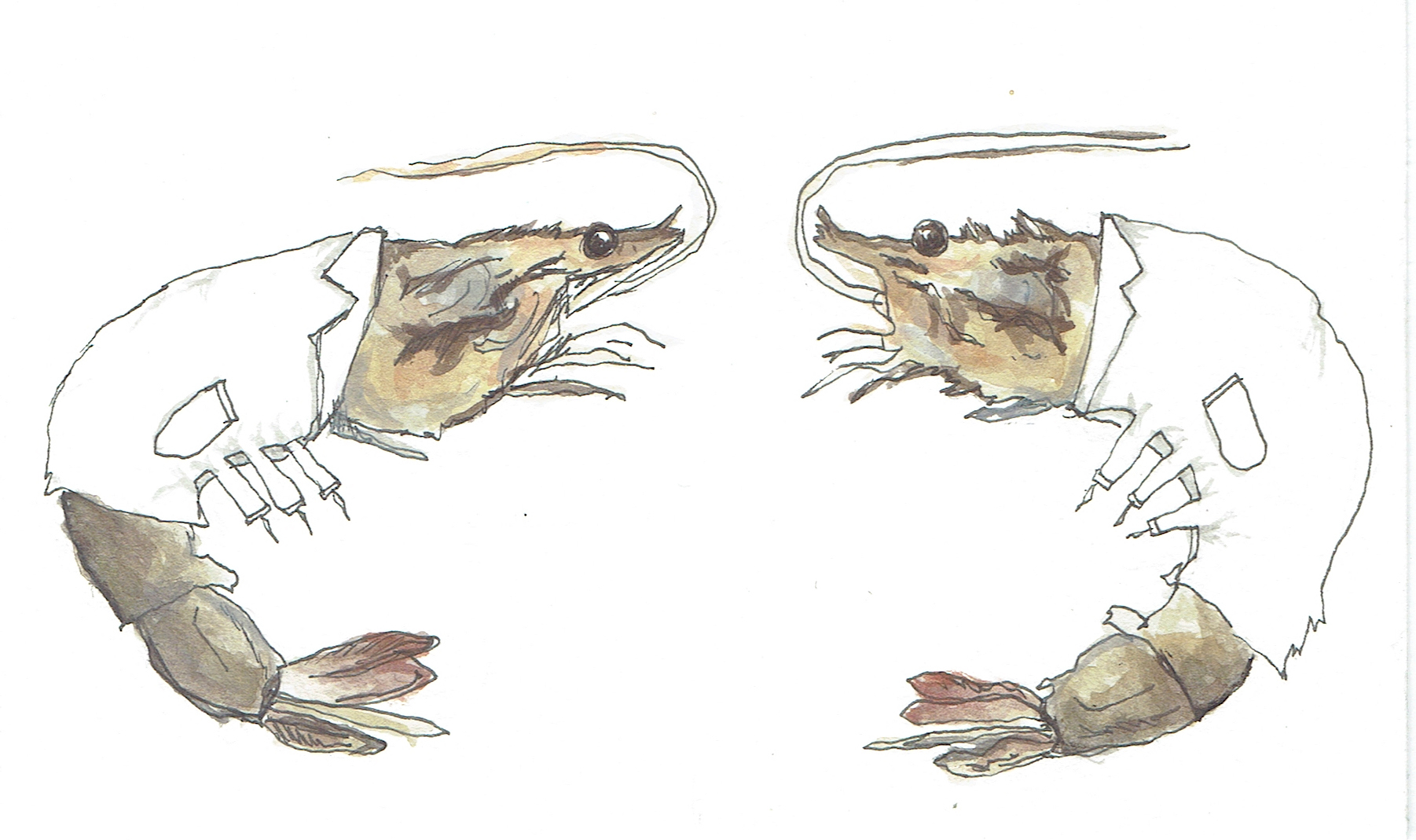

Dominique has an unusual background for a startup founder, but one that completely explains her product focus. She did a stint working the shark tank at Golden Nugget the casino hotel in Las Vegas; she also worked at the marine mammal observatory for the Navy in San Diego, and holds a master’s degree in marine biodiversity and conservation from Scripps Institute of Oceanography.

Michelle is a graduate of Carnegie Mellon University with a bachelor’s in materials science and engineering and a master’s in biomedical engineering. They met through Jennifer Kaehms, another co-founder who had previous experience with startups but has since left the company. It was a match made in start-up heaven: Michelle could take Dominique’s passion for conserving sea life to the lab.

“I did a lot work with wound-healing therapies in school,” Michelle says. “Understanding how muscles are made up helped me in product development for shrimp when trying to mimic molecular structures.”

Dominique Barnes and Michelle Wolf are trying to change the way we eat seafood. Illustration by Catherine Lamb

Dominique Barnes and Michelle Wolf are trying to change the way we eat seafood. Illustration by Catherine Lamb

The New Wave Foods team wasn’t initially focused on shrimp; they wanted to create artificial shark fins. They imagined their fins could eliminate the rather gruesome practice of catching the animals, hacking off their fins, and throwing the shark’s body back into the ocean. Although shark fin soup has been popular in China for decades, it has fallen out of favor in the past few years.

“I think that shark finning is an issue that needs to be addressed, but as far as business is concerned the market is really niche and small,” Dominique says. “Shrimp just made more sense because the markets are bigger. It’s a very ubiquitous seafood, almost every culture and cuisines celebrate [with shrimp]. It’s the number one consumed seafood here in the U.S. So it just made sense as a way to grow a business but also to have a big impact to go after shrimp.”

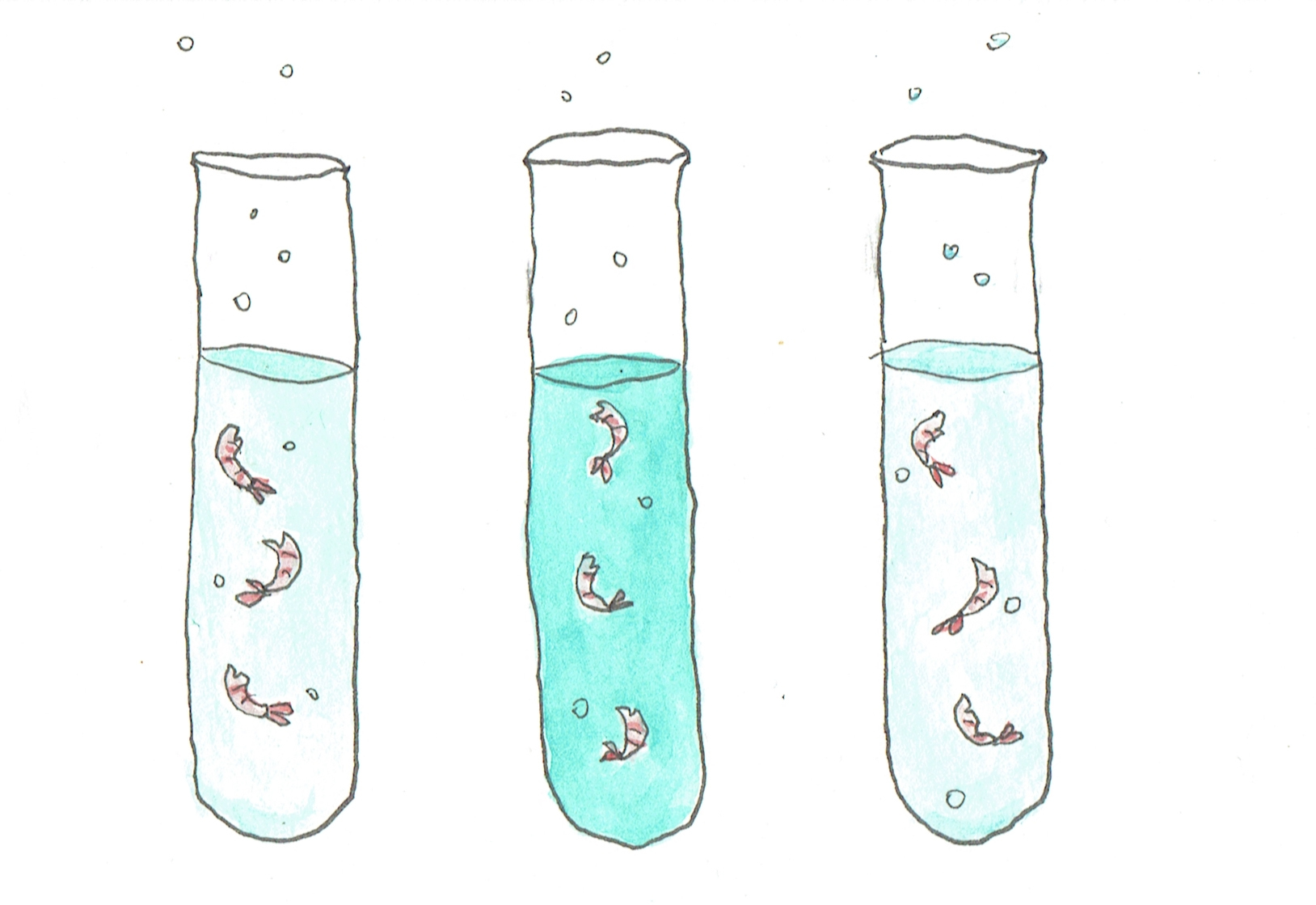

They created their “shrimp” out of plant proteins and bacterial polysaccharide, or carbohydrate. Melding the two ingredients forms part of the shrimp structure. “Our shrimp structure forms when we manipulate certain plant compounds,” says Michelle. “It can be likened to kneading bread to make it doughy. We’re not exactly kneading a mixture into shrimp but it’s a nice metaphor for the process.” For color and flavor they use the same red algae shrimp often eat in the wild, which gives them their pink color.

Illustration by Catherine Lamb

Illustration by Catherine Lamb

The team is currently working on “shrimp” 2.0.

“We want to get a nutritional content that is as close to shrimp as possible,” said Michelle. “Shrimp has about 25 grams of protein (per serving), and that’s what we’re aiming for. We’re working on our process to get something a little more fibrous that you just pull off and can dip into cocktail sauce,” Michelle said. They’re currently demo-ing their “shrimp” as popcorn shrimp, which hides some of the deviations from the traditional product.

While the creation of New Wave Foods’ shrimp is certainly a high-tech process, “all the ingredients that we use are already ingredients that are in our food system,” said Dominique. “It’s all things that you’ve probably eaten, maybe even in the last week, so it’s food that is food. It’s not…”

“A Franken-science project,” said Michelle, finishing Dominique’s thought.

Illustration by Catherine Lamb

Illustration by Catherine Lamb

Using real ingredients has plenty of benefits. By using ingredients that are widely available in the marketplace and already approved for consumption, New Wave can quickly scale up their shrimp production.

While some bioengineered food companies use stem cells from the animals to create their products, New Wave Food does not, thus making their “shrimp” safe for seafood allergy sufferers, and it’s vegan, too. New Wave Foods’ real ingredients have also appealed to the kosher community. They recently sold their shrimp to L’Chaim Foods, a kosher caterer.

They’ve already found some demand (they initially received a 200-pound order from Google), but can’t quite fill orders that large. They’ll need to figure out how to scale sooner than later, as demand for plant-based alternatives continues to grow.

“I guess you could call our product edible material science,” said Michelle. “But it’s really just food with a little bit more thought into it.”